Development Meeting

What is required for the function as an assembly = automobile function?

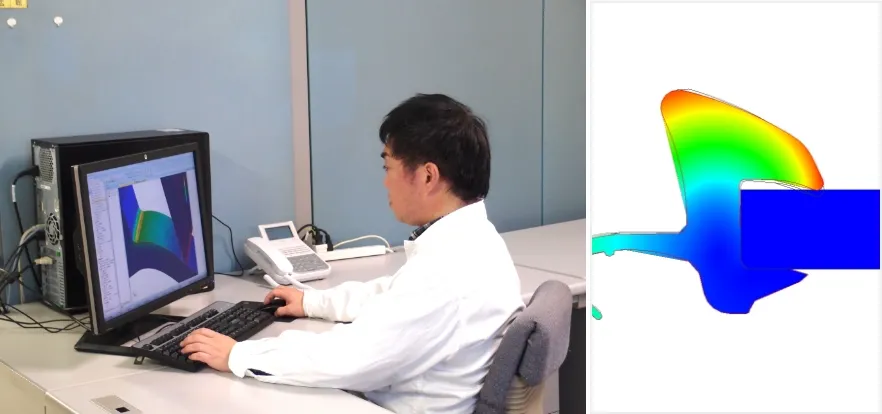

To meet customers’ demands considering environmental performance and safety, departments gather to decide on development themes that can provide new value to customers.